Plasma Spray Powders

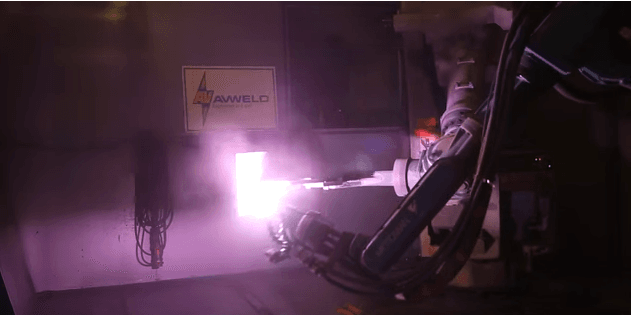

DC plasma spray operates by creating an electric arc and passing a plasma gas through it. This creates an extremely high temperature plasma, which enables ceramics to meet their melting temperatures. The following is a brief summary of common powders available.

For specific application expertise or any questions please contact our sales team.

| PART NO. | DESCRIPTION | APPLICATIONS |

|---|---|---|

| AI-1010 | Aluminium Oxide Ceramic Powder exhibiting high hardness and outstanding corrosion resistance. 65HRc. | Sliding wear surfaces such as pump shafts, mechanical seals, plungers, slurry pump liners. |

| AI-1011 | Aluminium Oxide ceramic powder developed primarily for plasma spraying | Sliding or rotating wear surfaces such as pump shafts and sleeves, mechanical seal faces, pump plungers, sealing rings etc. |

| AI-1025 | Chrome oxide ceramic powder exhibiting high hardness and outstanding corrosion resistance. | Applications up to 540°C requiring smooth, hard abrasion and corrosion resistance. Pump sleeves, wear rings, fans. |

| AI-1036 | Chrome oxide/silicon dioxide/titanium dioxide ceramic powder. The most abrasion resistant of the ceramic powders. Higher impact resistance than due to the presence of silicon dioxide. | Applications involving fine particle abrasion. Suitable for corrosive environments when properly sealed. |

| AI-1097 | Titanium dioxide. Dense coating. 53HRc. | Applications up to 540°C requiring abrasion resistance. Good for coating titanium components subject to wear. |