Chocky Blocks

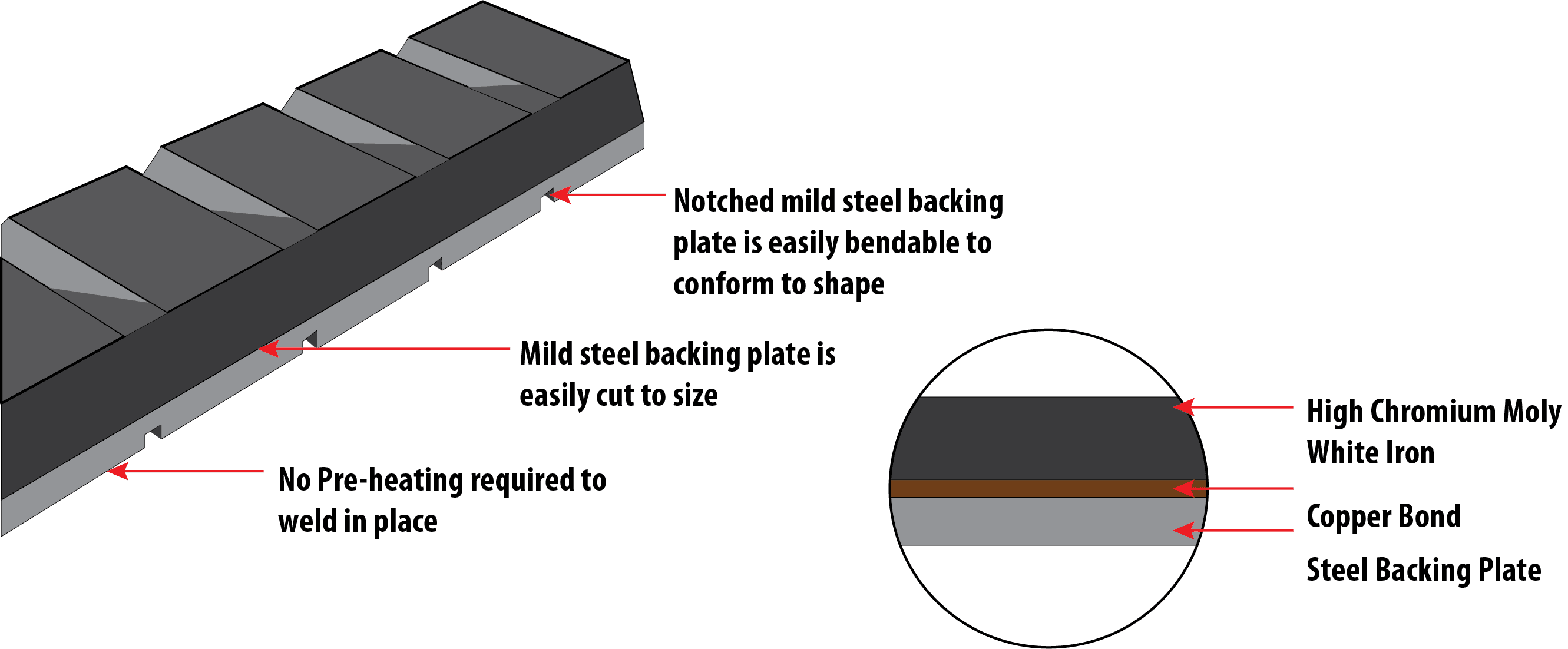

Chocky Blocks can be welded inside or outside any shaped surface to provide an extra level of protection for high impact and wear applications.

White Iron Wear Products

For high impact abrasion applications in material handling, you can’t go past Alloys International’s white iron wear products. The Chromium-Molybdenum white iron castings, are vacuum brazed onto a mild steel backing plate. The mild steel can be welded in situ for quick attachment to the wearing surface. No pre- or post- heat treatment required.

The high chromium and molybdenum casting incorporates super hard chromium carbides, 1500HV, in a martensitic matrix. Available in a wide range of sizes and shapes, the white iron products are especially suited to high impact and abrasion applications.

Chocky Blocks

Alloys ChockyBlocks look just like they sound. The notched bars can be easily broken into small segments for welding onto round or varied surfaces. They are suitable for fixed and mobile plant, such as buckets, trays, chutes, crushers and impact plates.

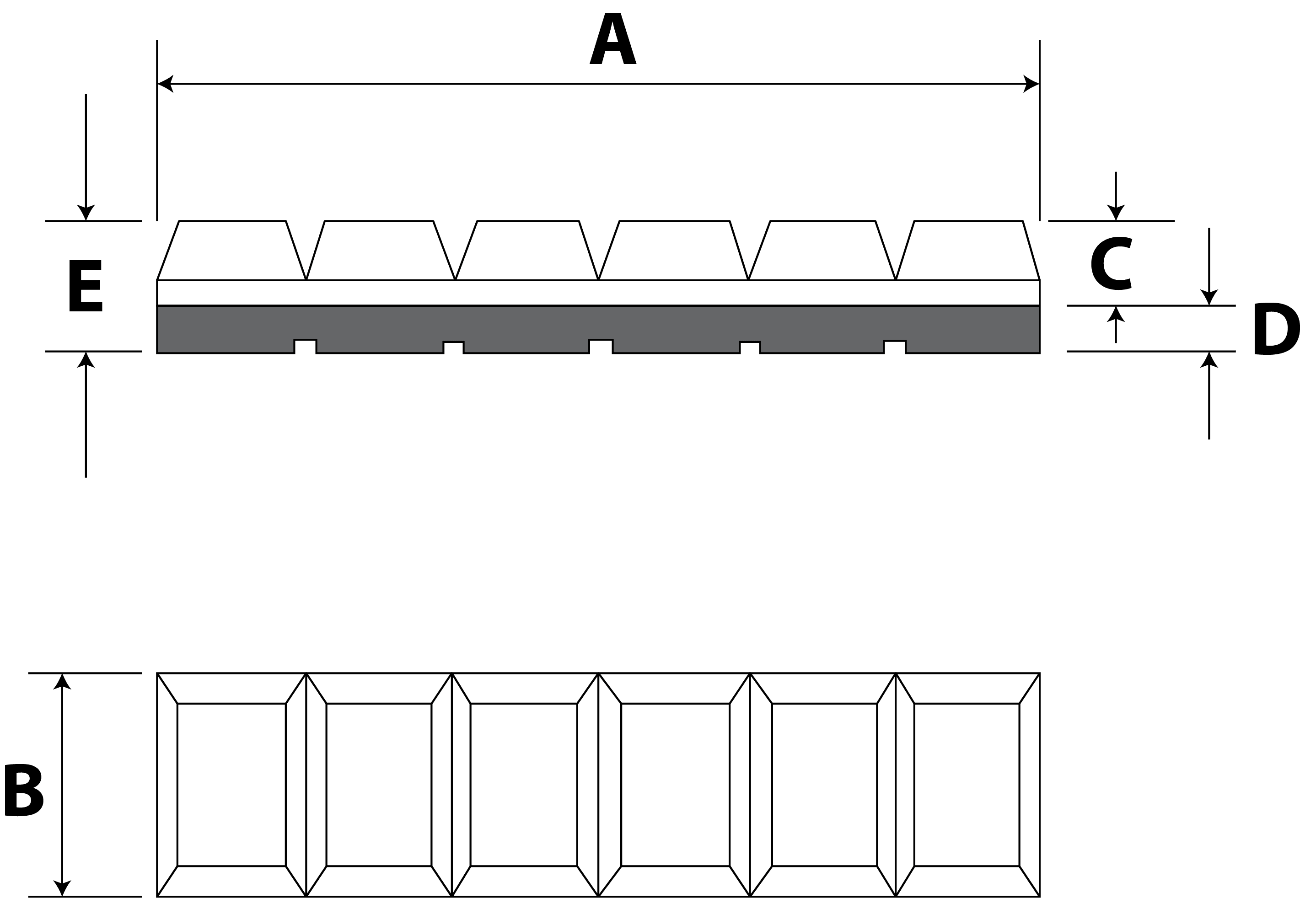

SIZES

| Part Number | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | Weight (Kg) |

|---|---|---|---|---|---|---|

| AL-BC25-N | 240 | 25 | 15 | 8 | 23 | 0.90 |

| AL-CB40-N | 240 | 40 | 15 | 8 | 23 | 1.50 |

| AI-CB50-N | 240 | 50 | 15 | 8 | 23 | 1.90 |

| AI-CB65-N | 240 | 65 | 15 | 8 | 23 | 2.50 |

| AI-CB90-N | 240 | 90 | 15 | 8 | 23 | 3.50 |

| AI-CB100-N | 240 | 100 | 15 | 8 | 23 | 3.90 |

| AI-CB130-N | 240 | 130 | 15 | 8 | 23 | 5.15 |

| AI-CB150-N | 240 | 150 | 15 | 8 | 23 | 6.20 |

Advantages

Longer wear life: outlast Q&T steel.

Reduced downtime: improve equipment life and require less maintenance and inspections.

Easy to fit: No special qualifications required to weld. As an alternative to welding, studs can be attached on request.

Flexibility: we can supply block products for attachment in the field as required, or they can be pre-attached to equipment.

Adaptability: available in a wide range of dimensions and can be adapted to suit a wide range of operating conditions.