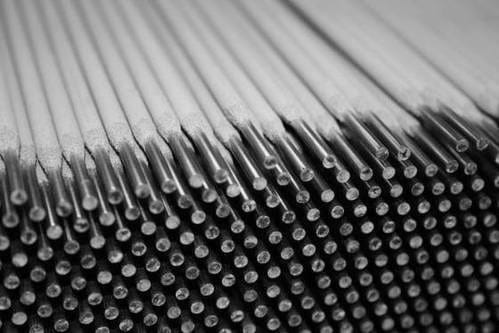

LOW ALLOY STEEL

Steel maintenance and fabrication electrodes, rods, wires

Alloys International provide a full range of low alloy fabrication, repair and maintenance welding consumables, including Stick Electrodes (SMA), TIG rods (GTAW), Cored wires, MIG/MAG solid wires, Submerged arc wires and flux (SAW).

When looking for fabrication consumables, Alloys have the expertise to recommend the correct product for your job. We have access to the full Voestalpine Bohler Welding product range, and high local stock.

LOW ALLOY STEEL CONSUMABLES

| PART NO. | SPECIFICATION/S | DESCRIPTION & APPLICATIONS |

|---|---|---|

MANUAL METAL ARC ELECTRODES |

||

| AI-0111-TDS | AS/NZS 1553.1:E4112-0 AWS/ASME A5.1:E 6013 | A universal electrode especially developed for use in the maintenance field for welding in all positions (including Vertically Down) of badly prepared sheets of steel of all thicknesses, badly adjusted joints and of steel contaminated by paint, corrosion etc. Electrode has the feature of being able to be used on welding sets operating on very low open circuit voltages. |

| AI-0118-TDS | AS/NZS 1553.2:E7618-M H5R AWS/ASME A5.5:E11018M H4 | AI-0118 was developed for the welding of the quenched and tempered constructional alloy steels (eg Bisalloy, Hardox) having a yield strength of 685-880 MPa (100,000 – 130,000 psi). AI-0118 is designed for joining and cladding on a wide range of construction equipment, heavy machinery in a varied range of heavy industries. The electrode is suitable for welding high strength steels where high impact values at low temperatures are required. Easy slag removal. |

| AI-0150-TDS | AS/NZS 4855-B – E49 16-A U H10 AWS/ASME A5.1: E7016 H8 | A high strength, low hydrogen electrode developed especially for the maintenance welding industry. Used for welding of joints subject to high stress or restraint. Features include a double coating to reduce the susceptibility of moisture pick-up and the ability to weld with very low amperages. Also, easily form double beads in all positions welding with a short arc. Very good X-ray properties. AI-0150 is distinguished by easy weldability. Its easy running characteristic make it ideal for poorly fitted joints, insufficient weld preparation and hard to reach areas. |

| AI-0178-TDS | AS/NZS 1553.2 : E4818-A1 H5R AWS/ASME SFA A5.5: E7018-A1 H4R | Universal basic coated electrode with 115% recovery, for welding highly stressed connections with high success. Good low temperature properties down to -500C. Highly resistant to cold cracks. Stable Arc with easy removable flux. Uses include Frames, cases, ship building and pressure vessels. Construction Steels for general use, Tube Steels, Ship Steels, Steels for Boiler and Pressure Vessels, High Strength steels, Heat resistant steels, Cold tough steels. |

| AI-0178H-4R-TDS | AS/NZS 1553.1 : E4818-5 H5R AWS/ASME A5.1: E7018-1 H4R | Universal basic coated electrode with 115% recovery, for welding highly stressed connections with high success. Good low temperature properties down to -500C. Highly resistant to cold cracks. Stable Arc with easily removable flux. Uses include Frames, cases, ship building and pressure vessels. Construction Steels for general use, Tube Steels, Ship Steels, Steels for Boiler and Pressure Vessels, High Strength steels, Heat resistant steels, Cold tough steels. |

| AI-01EV50-1 | AWS A5.1 E7018-1H4R AWS A5.1M E4918-1H4R EN ISO 2560-B E 49 18-1A U H5 | AI-01EV50-1 is a basic covered electrode with very good welding characteristics including out of position work. It has particularly good impact properties down to -50oC and CTOD tested at -10oC. Weld metal recovery about 115%. AI-01EV50-1 is crack-free weld metal when welding high-carbon steels. Very low hydrogen content in the weld metal (under AWS conditions HD≤4ml/100gm) Applications: Suitable for use in tank construction, boiler and pressure vessel manufacturer, apparatus engineering, vehicle manufacture, offshore applications and ship building. Suitable for welding steels with low purity and high carbon content. |

| AI-0180-TDS | AS/NZS 1553.2:E5518-B2 H5R AWS/ASME A5.5: E 8018-B2 H4 | Universal basic coated electrode for welding of high temperature steels. Suitable for applications up to 550oC. Used for welding Chrome Moly pipes, plates and castings. Used in the petrochemical, refineries, paper and power industries. Can also be used to weld Chrome Moly to Carbon Steel and for case hardening steels. |

| AI-0190-TDS | AS/NZS 1553.2 : E6218-B3 H5R AWS/ASME A5.5 : E9018-B3 H4 | 2.25Cr-1Mo content to be used for the welding of creep resistant steel. It is used in chemical industry and in the ammonia synthesis process, for heat exchangers, boilers, piping and pressure vessels for temperature service up to about 600°C. It will also find application in the petro-chemical industries, suitable for facing on casting and for casting repairs. |

GAS SHIELDED CORED WIRE |

||

| AI-1705-TDS | AWS/ASME A5.28 : ER90S-B3 | 2.25Cr-1%Mo content to be used for the welding of creep resistant steel. AI-1705 is a Low alloy copper-coated solid wire with 2.25% Cr and 1% Mo content to be used for the welding of creep resistant steel. Chemical composition conforming to classification: AWS A 5.28: ER90S-B3. It is used in the chemical industry and in the ammonia synthesis process. Applications include: Heat exchangers, boilers, piping & pressure vessels for temperature service up to about 600°C. It will also find applications in the petro-chemical industries, suitable for facing on casting and for casting repairs. To be used under the shield of Ar+CO2. |

| AI-1735-TDS | DIN 8555 MF 6-GF-50-CT | Special Iron-Chromium-Cobalt-Molybdenum alloy designed to resist metal-to-metal wear, fatigue, oxidation, cavitation and corrosion at high temperature. The typical hardness can be achieved in the first layer. |

| AI-1742FC-TDS | AWS/ASME A5.29: E 110 T5 –K4 H4 110 S-G E 110 T5 –K4M H4 | AI 1742 FC is a seamless copper coated, low alloy steel wire. Recommended for all positional Gas Metal Arc Welding of high strength steels. It produces a low alloy (nominally, 1.4%Ni, 0.4%Cr, 0.30&Mo, 0.10%V) steel weld deposit of the 690 MPa tensile class. Good low temperature properties and controlled bead shape. Applications: Ideal for welding of high tensile steels particularly the notch tough, quench and tempered types such as Bisalloy 80, HY 100, USST1 and Welten 80. Resultant weld deposits have excellent toughness in the “as welded” condition. |

| AI-1771-TDS | AWS/ASME A5.20-05: E71T1-M21A4-CS1-HB | Rutile flux cored wire with fast freezing slag. AI 1771 is an all-positional wire providing good weldability with easy slag detachability. Low spatter, smooth finely rippled seam surface, notch free weld toes. Out of position welding can be carried out with increased welding current, resulting in increased deposition rates. Applications include: Steels up to a maximum strength of 460 MPa with shielding gas M21. Shipbuilding steels A, B, D, E, A 32-E36. ASTM A 106 Gr A, B, C |

| AI-17 HL46-T-MC | AWS A5.36 E70T15-M21A2-CS1-H4 | Seamless all positional metalcored wire for semi-automatic and fully automatic joint welding of unalloyed and fine-grained constructional steels utilizing service temps from -30°C to +450°C. Steady spray arc-like droplet transfer with minimal spatter formation. High resistance to porosity, good wetting behaviour as well as low hydrogen contents (≤ 5 ml/100 g deposit) are further quality features of this metal-cored wire. Ideal for horizontal and flat fillet welds. This wire is designed for minimum oxide residues permit the welding of multi passes without the need for inter-run cleaning. |

| AI-17 HL51-T-MC | AWS A5.36 E70T15-M21A8-CS1-H4 | Seamless metal cored wire for single- or multilayer welding of Carbon, Carbon-Manganese and similar types of steels, including fine grain steels with Argon-CO2 or pure CO2 shielding gas. Features include: high yield, good weldability, excellent bead appearance, very low spatter losses and exceptional mechanical properties at low temperatures (-60°C) in as welded conditions as well with post weld heat treatment. This wire is especially suitable for automated-robotized applications and for root pass welding for piping and butt-joints. |

| AI-17 HL53-T-MC | AWS A5.36 E80T15-M21A8-Ni1-H4 | Seamless all positional metalcored wire, Nickel alloyed, metal cored wire for single- or multilayer welding of carbon, carbon-manganese and high strength steels with Ar-CO2 shielding gas. Features include: high yield, good weldability, excellent bead appearance, very low spatter losses and exceptional mechanical properties at low temperatures (-60°C) in as welded conditions as well after post weld heat treatment. This wire is especially suitable for root-pass welding in off-shore and pipeline applications. |

FLUX CORED OPEN ARC WIRE |

||

| AI-1500-TDS | AWS/ASME A5.20.79: E71-T11 AS/NZS 2576-2203-B7 | AI-1500 is a self-shielded welding wire for general purpose welding in all positions. Used on DC electrode negative, the wire has a smooth spray transfer even at low currents and arc voltages. Unlike gas-shielded wires where a short wire stick out of 10-15 mm is preferred, the self-shielded wires require a longer stick out of 25-50 mm. This is so that the heating effect on the wire will cause the gas shielding materials to decompose and provide the shield. Too short a stick out does not allow the shield to form and porosity can result. AI-1500 is designed to operate in spray transfer mode at lower amps and voltages than is usual for a particular wire diameter. The low heat input makes it particularly suited for fabrication of thin gauge materials. Applications: All position single and multi-pass welding of mild and low alloy steel where impact properties are not required. Particularly suited for high speed welding of thin gauge material. General purpose welding in all positions where operators appeal is main consideration. |

| AI-15306-TDS | AI-15306 is a easy to use self-shielded welding wire for use by a wide range of welders whether experienced or not. It is designed for high deposition rate welding for build-ups, butt and fillet welds. It is a versatile, easy to use wire with excellent operator appeal. It has a soft arc which makes it easy to use for gaps and large misfits. Depositing a weld that is low in sulphur and this then in turn offers increased resistance to hot cracking. It is designed to be used with a long stick out and the flux cored capability makes it ideal to use onsite applications. Applications include: Build-up of large castings, large fillet welding. Good operator appeal. |

|

MIG SOLID WIRE |

||

| AI-1700-TDS | AS/NZS 2717.1 – 1984 AWS/ASME A5.18-79 : ER70S-6 | AI-1700 is a sound GMAW wire that provides the welder with high deposition rates and recovery rates up to 95 per cent. The wire is precision layer wound and copper coated for trouble-free feeding. Applications: AI-1700 can be used for both dip transfer and spray transfer. |

| AI-1703-TDS | AWS/AWSE A 5.28: ER80S-D2 | AI-1703 is an all-positional, alloyed solid MIG wire for the welding of high strength steels. Due to its higher deoxidant levels this wire offers excellent porosity free welds on dirty and rusty steels. Applications: AI-1703 is ideal for the welding of boilers, pressure vessels, pipelines as well as many applications in earthmoving and mining such as welding segments to ring gears and other areas where the component is subjected to dynamic loadings. With an elongation rating of 24% this alloy offers good resistance to cracking where parts may be constrained. Deposits of AI-1703 may be removed by flame cutting. |

| AI-1704-TDS | AWS A 5.28: ER80S-B2 | AI-1704 is 1.25Cr-0.5Mo content to be used for the welding of creep resistant steel. Applications include: Chemical composition of AI-1704 conforming to AWS specification. It is used in chemical industry and in the ammonia synthesis process, for heat exchangers, boilers, piping and pressure vessels for temperature service up to about 550°C. It will also find applications in the petro-chemical industries, suitable for facing on casting and for casting repairs. To be used under the shield of Ar+O2. |

| AI-1740-TDS | AWS/ASME ER 80S-B2 | Copper coated Cr-Mo alloyed wire for MIG welding of high temperature steels. Suitable for applications up to 550° C and for welding of heat treatable steels of similar composition. |

| AI-1742-TDS | AWS/ASME A5.29: ER 110 S-G | AI-1742 is a copper coated, low alloy steel wire suitable for the all positional Gas Metal Arc Welding of high strength steels. AI-1742 produces a low alloy (nominally, 1.4%Ni, 0.4%Cr, 0.30&Mo, 0.10%V) steel weld deposit of the 690 MPa tensile class. Applications: Ideal for welding of high tensile steels particularly the notch tough, quench and tempered types such as Bisalloy 80, HY 100, USST1 and Welten 80. Resultant weld deposits have excellent toughness in the “as welded” condition. |

| AI-1766-TDS | AWS/ASME A5.28 : ER90S-B3 | AI-1766 is a gas shielded, copper coated, solid MIG wire designed for joining and / or overlaying of high temperature and creep resistant steels. This wire is typically used for welding 2 ¼ Cr 1 Mo or ½ Cr ½ Mo ¼ V steels. These alloys are usually found in the petro-chemical or power generation industries. |

SUB ARC WIRE & FLUX |

||

| AI-1600-TDS | DIN 8555 : UP I-GF-250-P | AI 1600 is a sub arc-rebuilding alloy for carbon steel parts. Applications include: Crawler tractor links, crane wheels, shafts, buffer layer for continuous casting rolls, mine car wheels and other area that require build-ups. |

| AI-1635-TDS | AI-1635 is a special IRON-CHROMIUM-COBALT-MOLYBDENUM ALLOY designed to resist metal-to-metal wear, fatigue, oxidation, cavitation and corrosion at high temperatures. The deposit is crack-free and typical hardness is achieved in the first layer. Applications include: Continuous casting drive rolls, dies, mandrels, punching tools, forming tools, pump elements etc. | |

| AI-16 Record 605 TDS | ISO 14174 SA FB 1 65 DC H5 | UTP RECORD 605 is an agglomerated flux for submerged arc welding. It is recommended for surfacing application especially with different unalloyed and low alloyed SAW wires. It has neutral metallurgical behaviour and provides excellent slag detachability even at high interpass temperatures. Suited for welding with single and multi-wire configurations. The flux is mostly applied with solid and with flux-cored wires for hard-facing applications up to hardness up to 50HRC. |

| AI-16 Record SK TDS | EN 760 SA FB 3 | Special agglomerated flux for hardfacing with high Nitrogen containing flux cored wire as SK 742N-SK. Very good slag removal and weld bead appearance make this flux particularly suitable for the hardfacing of continuous casting rolls. |

| AI-16 T55 HP UV 306 | AWS A5.17 / SFA-5.17 F7A5-ECG | SUBARC T55 HP – UV 306 is a wire-fl ux combination for submerged arc welding of unalloyed structural steels and fi ne-grained structural steels up to MSYS = 500 MPa. The weld metal demonstrates relative good toughness properties at low temperatures and can be used in a very wide range of applications. The aluminate-rutile fl ux has a relative low basicity index and is selected for its excellent welding properties and is suitable for high welding speed. Also a very good welding behavior in PC position and for 2-run technology this combination shows an improved welding behavior (nicer bead appearance and higher welding speed) compared to a solid wire. The wire is a coppered seamless basic fl ux cored wire with a good resistance to deformation (wire feed rollers) and is very easy to straighten to ensure the best current transfer with a low contact tip consumption. The wire is not sensitive to moisture pick up. |

| AI-16 T55 HP UV 419 | AWS A5.17 / SFA-5.17 F7A8-EC1 / F7P8-EC1 | T55 HP – UV 419 TT-W is a wire-flux combination for submerged arc welding of unalloyed structural steels and fine-grained structural steels up to MSYS = 460 MPa. Especially recommended for applications with PWHT. The weld metal maintains very good strength properties after relative long PWHT durations (e.g. pressure vessels 16 hours at 620ºC). The wire is a coppered seamless basic flux cored wire with a good resistance to deformation (wire feed rollers) and is very easy to straighten to ensure the best current transfer with a low contact tip consumption. The wire is not sensitive to moisture pick up. |

| AI-16 T55 HP UV 421 | AWS A5.17 / SFA-5.17 F7A8-EC1 / F7P8-EC1 | T55 HP – UV 421 TT is a wire-flux combination for submerged arc welding of unalloyed structural steels and fine-grained structural steels up to MSYS = 460 MPa. The weld metal demonstrates very good toughness properties at low temperatures. The wire is a coppered seamless basic flux cored wire with a good resistance to deformation (wire feed rollers) and is very easy to straighten to ensure the best current transfer with a low contact tip consumption. The wire is not sensitive to moisture pick up. |

| AI-16 Union S EM12K UV 401 | AWS A5.17 F7A5-EM12K F7P5-EM12K | Union S EM12K – UV C 401 is a wire flux combination for joining and surfacing applications with general-purpose structural steels, boiler and pipe steels. The flux is characterized by low Silicon and moderate Manganese pick-up. The welding characteristics are good producing a smooth weld bead with excellent slag detachability. |

| AI-16 Union S EM12K UV C 305 | AWS A5.17 F7AZ-EM12K | Union S EM12K – UV C 305 is a wire flux combination for joining applications with general purpose steels. It is particularly well-suited for single-wire or twin-arc fillet welding with small wire diameter (e.g. with 2.0 mm) with high welding speed. Wall thickness <10 mm. The flux is characterized by low silicon and moderate manganese pick-up. The welding characteristics are good producing a smooth weld bead with excellent slag detachability. |

| AI-16 UV C Flux 401TT | AWS A5.17 F7A5-EM12K F7P5-EM12K | Union S EM12K – UV C 401 is a wire flux combination for joining and surfacing applications with general-purpose structural steels, boiler and pipe steels. The flux is characterized by low Silicon and moderate Manganese pick-up. The welding characteristics are good producing a smooth weld bead with excellent slag detachability. |

| AI-16 UV Flux 305 | ISO 14174 SA AR 1 76 AC H5 | UV 305 is an aluminate-rutile agglomerated flux with medium Si and Mn pick-up for joining un-alloyed and low alloyed steel grades. The flux finds its most important applications in high speed fillet welding, especially fin-to-tube in water-wall construction for thermal power generation (boiler), with Union S 2 Mo, S 2 CrMo, S 1 CrMo 2 and S P 24, however also with unalloyed wires in general purpose applications. Also very good performance in two-run technique (longitudinal and circular seams), especially for very thin wall thickness. Wall thickness is recommended up to 10 mm. It has outstanding good slag detachability (even in narrow grooves) and allows high welding speed. Best welding performance is with DC+ current with single wire and Twin-arc process. |

| AI-16 UV Flux 418TT | ISO 14174 SA FB 1 55 AC H5 | UV 418 TT is an agglomerated flux of fluoride basic type for joining and surfacing and applications with dissimilar steels. Mainly for high strength and cryogenic fine grained structural steels. The Si and Mn pick-ups and burn-off rates are neutral because of its metallurgical behaviour. The flux is weldable with almost every wire electrode. When used in combination with Union S 3 Si wire electrode, the weld metal has high toughness properties up to –60 °C (–76 °F) and very good CTOD values up to –30 °C (–22 °F), so that this combination is outstandingly suited for offshore constructions. The flux can be used for tandem and multi-wire welding with DC and AC. Very good slag detachability. |