White Iron Wear Parts

High quality chromium-molybdenum, white iron castings metallurgically bonded to a weldable mild steel backing plate

White Iron Wear Products

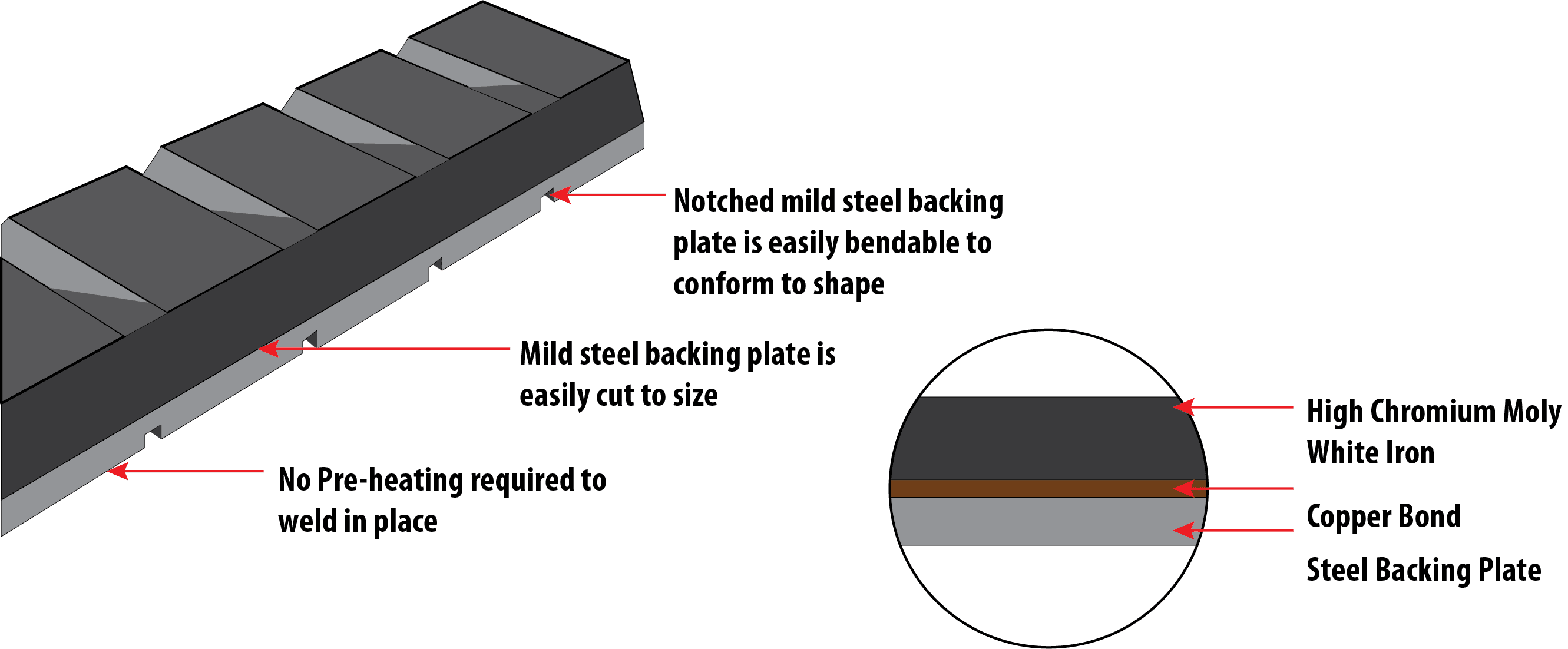

For high impact abrasion applications in material handling, you can’t go past Alloys International’s white iron wear products. The Chromium-Molybdenum white iron castings, are vacuum brazed onto a mild steel backing plate. The mild steel can be welded in situ for quick attachment to the wearing surface. No pre- or post- heat treatment required.

The high chromium and molybdenum casting incorporates super hard chromium carbides, 1500HV, in a martensitic matrix. Available in a wide range of sizes and shapes, the white iron products are especially suited to high impact and abrasion applications.

Chocky Blocks

The notched bars can be easily broken or formed to be welded

onto any surface to provide an extra level of protection for wear and

impact applications. They are suitable for fixed and mobile plant wear

protection such as buckets, excavators, trays, chutes, crushers and

impact plates.

Wear Buttons

Industry proven to combat Impact and Abrasion Wear. Excellent results on bucket & shovel protection, supports life of ground engaging tools.

The unique profile of the Button deflects material. Ideal for tooth adapter protection & bucket side wall protection.

Various sizes make them well suited for small & awkward areas requiring wear protection.

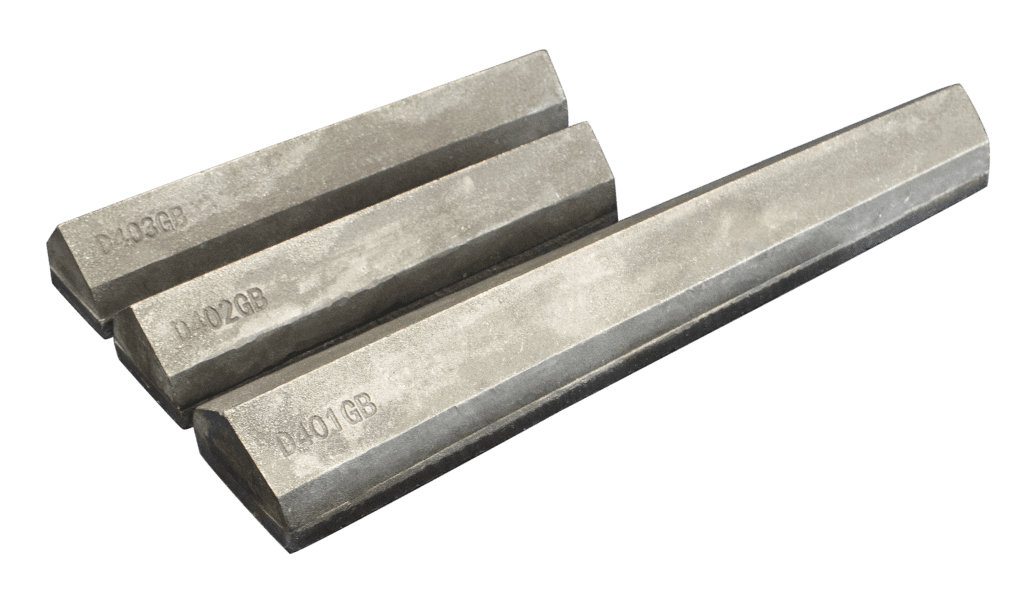

Grizzly Bar Liners

Grizzly Bar liners come with sloped top white iron cast shape, to provide the best combination of impact and wear resistant materials for protecting your screen and crash decks.

KEY POINTS

- Superior wear resistance results in higher consistency of ore size feeding your crushing circuit.

- Improve performance in downstream, secondary and tertiary crushing.

- The peaked profile improves efficiency, ensuring all material passes over the screen slits.

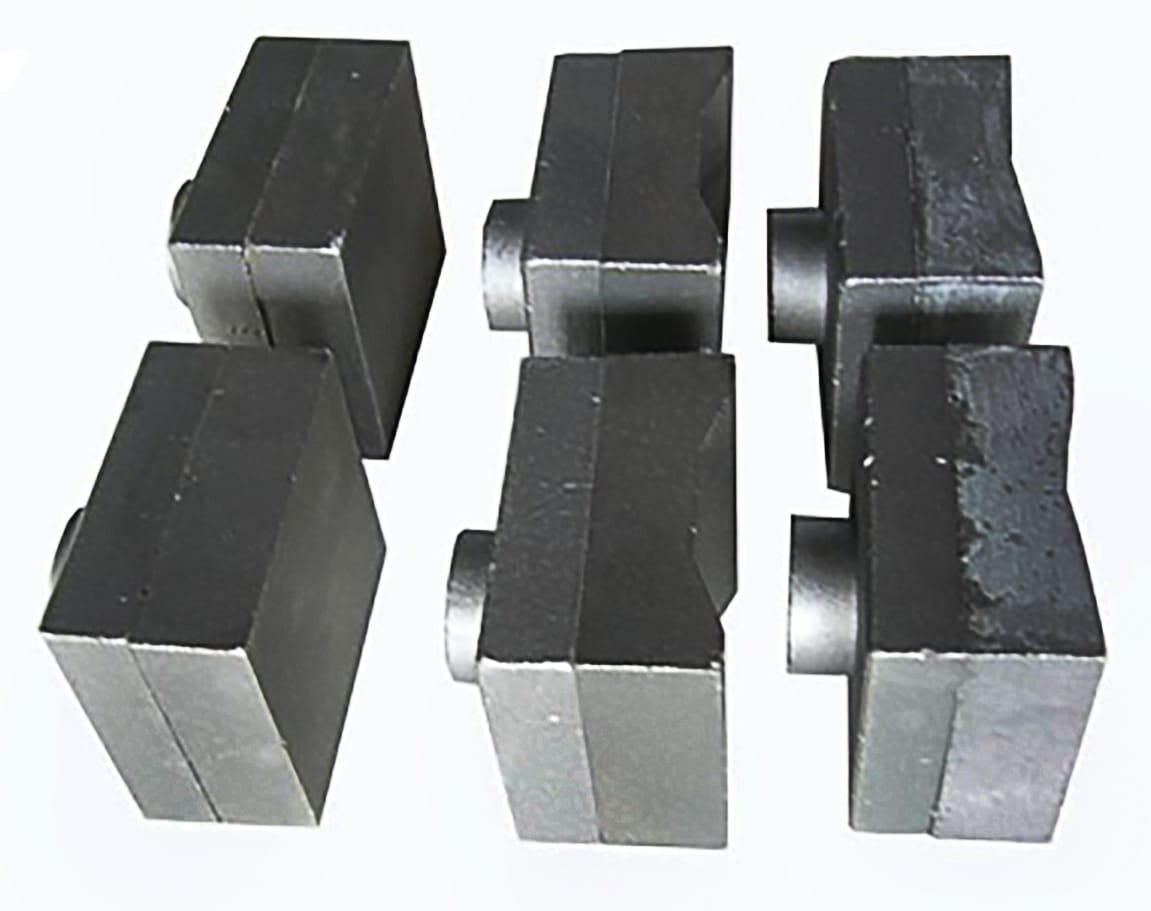

Shredder Hammer Tips

Standard, Flared & Butterfly Shapes

- Machined steel base allows for quick & easy in-situ installation

- Cost effective as compared to hard facing

- Superior edge retention & sharpness

- No need to rebuild edges

- Geometric & Engineered design to increase wear life

- Tips can be rotated for maximum wear life