HARDFACING CONSUMABLES

Alloys International are Australia’s foremost experts on hardfacing. We have been supplying hardfacing consumables for almost 40 years. With high local stock, we are able to provide the right advice for protection against abrasion, corrosion, high temperature, impact or any combination thereof.

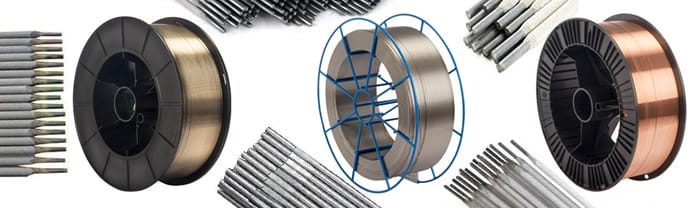

Products available include Stick Electrodes (SMA), TIG rods (GTAW), Cored wires, MIG/MAG solid wires, Submerged arc wires and flux (SAW), electroslag strip cladding strip and flux (ESW), and powders for Laser or PTA welding.

| Form | PART NO. | SPECIFICATION/S | DESCRIPTION & APPLICATIONS |

|---|---|---|---|

| SMAW Hardfacing Stick Electrode | AI-0501 | AS/NZS 2576 : 1215-A4 W.T.I.A Tech Note 4 : 1215-A4 | Basic coated electrode for surfacing parts subject to heavy impacts. Joining of 14% Mn steels. Underlay prior to hard surfacing. Applications include: railway equipment (Mn steel), large crusher parts, crusher hammers, toothed shells of coke cutters, shovel and dredging buckets. |

| SMAW Hardfacing Stick Electrode | AI-0535 | AS/NZS 2576 : 2355-A1 W.T.I.A. Tech Note 4 : 2355-A1 | Synthetic basic coated electrode with high recovery (160%) for hardfacing. Resisting mineral wear by friction, combined with shocks and compression – austenitic matrix containing Cr carbides. Pleasant fusion – self releasing slag – deposit resists to corrosion (32% Cr) and to hear up to 200oC. Eventual surfacing in 1, 2 or 3 layers – for all pieces subject to high abrasion combined with a good resistance to shocks. Only machinable by grinding. Applications include: excavating and crashing equipment, surfacing of endless screws, mixer blades, pump bodies for abrasive materials, concrete pumps, ore crushing, press screws for bricks. |

| SMAW Hardfacing Stick Electrode | AI-0538 | AS/NZS 2576 : 2360-A4 W.T.I.A. Tech Note 4 : 2360-A4 | Hardfacing electrode with high efficiency basic coating (190%). Highly resistance to abrasion due to its high content of Cr and C: the service life of surfaced piece can be 50 times longer as for conventional electrodes of similar hardness. Austenitic matrix with Cr carbides – resistance to moderate shock – deposit 1 or 2 layers max – agreeable fusion – no slag – bead very smooth. For all pieces subject to low or moderate shock where an important resistance to abrasion is required. The formation of cracks on the metal deposit is normal for this type of deposit. Applications include: Crusher parts, conveyor screws, excavator teeth, crushing of mineral materials, concrete pumps, ploughshare, pump bodies for abrasive materials. |

| SMAW Hardfacing Stick Electrode | AI-0538T | AS/NZS 2576 : 2355-A1 W.T.I.A. Tech Note 4 : 2355-A1 | AI-0538T is a tubular electrode depositing an Austenitic Chromium White Iron. Direct application to Austenitic Manganese Steels and Carbon Steels is possible. AI-0538T has a moisture resistant coating. There is no alloy contribution from the flux. Relief checks are normal in deposits. Multi layers up to three runs acceptable. Features fume control and ease of running. 6.0 mm may be easily used in out of position deposits. No preheat required on mild steel or grey iron. |

| SMAW Hardfacing Stick Electrode | AI-0540 | AS/NZS 2576 : 2450-A4 W.T.I.A. Tech Note 4 : 2450-A4 | Basic coated, high recovery electrode for surfacing parts subject to severe abrasion combined with high impacts. Applications include: Gyratory crusher hammers, coke cutters, wear plates on hoppers, vibrating screens, scrap collector plates, star crushers and rolls crushers. This alloy can be welded onto 14% Manganese steel without underlay. |

| SMAW Hardfacing Stick Electrode | AI-0543 | AS/NZS 2576 : 2460-A4 W.T.I.A. Tech Note 4 : 2460-A4 | High recovery, basic coated electrode for surfacing parts subject to severe abrasion with medium impacts at temperatures not higher than 450°C. Applications include: Screws of refractory material presses, screws of brick presses, and screws of cement presses. This alloy also has the characteristic of achieving full hardness in the first layer. |

| SMAW Hardfacing Stick Electrode | AI-0543T | AS/NZS 2576 : 2460-A1 W.T.I.A. Tech Note 4 : 2460-A1 | AI-0543T is a tubular electrode designed to give very good impact resistance yet retain a high hardness. There is less relief checking than Austenitic White Irons. 6.0 mm may be deposited out of position. Moisture resistant coating. No alloy contribution from the flux. Multi layers up to three runs acceptable. No preheat required on mild steel or grey iron. AI-0543T deposits complex carbide alloy. Applications include: Rail ballast tampers, crusher hammers, dredge teeth, dozer end plates, ripper teeth, grizzly bars and steel work mill guide. |

| SMAW Hardfacing Stick Electrode | AI-0545 | AS/NZS 2576 : 2460-A4 W.T.I.A. Tech Note 4 : 2460-A4 | Basic coated electrode for surfacing parts subject to extremely severe abrasion with medium impacts at temperatures up to 600-650°C. Applications include: Sinter crushers, scraper wires in zinc industries, scrap collectors, mechanical strokers and blast furnace chutes. |

| SMAW Hardfacing Stick Electrode | AI-0553T | AS/NZS 2576 : 2360-A1 W.T.I.A. Tech Note 4 : 2360-A1 | AI-0553T is a tubular electrode containing tungsten carbides in a matrix of chromium carbide designed to give excellent abrasion resistance and moderate impact resistance at high hardness. The 6mm electrode can be used out of position. Deposits will relief check. Up to two passes may be applied. AI-0553T has a moisture resistant flux coating. There is no alloy contribution from the flux. No preheat is required for direct application to grey cast iron or low alloy steel. Applications include: Rail ballast tampers, Dredge Teeth, Grizzly Bars, Mixer paddles, Steel mill guides, brickworks components etc. |

| SMAW Hardfacing Stick Electrode | AI-0554T | AS/NZS 2576 : 2355-A1 W.T.I.A. Tech Note 4 : 2355-A1 | AI-0554T is a tubular electrode, which has lower carbon and chromium than AI 558T to give improved impact performance. • Features ease of deposition, controlled fume. • Minimum or no splatter. Deposits will relief check. • Multi layers may be applied Moisture resistant flux coating. • No preheat required for direct application to grey cast iron or low alloy steel. Applications include: Brickworks Swing and Fixed Hammers, Ripper Teeth, Dozer End Plates, Dredge Teeth, Grizzly Bars, etc. |

| SMAW Hardfacing Stick Electrode | AI-0560 | AS/NZS 2576 : 1860-A4 W.T.I.A. Tech Note 4 : 1860-A4 | AI-0560 is a basic coated electrode for hardfacing. AI-0560 is a martensitic carbide providing good abrasion and medium impact resistance. It is excellent for resistance against compressive stresses and impact. Applications include: Parts of steel, cast steel, high Mn steel, subject to simultaneous impact, abrasion and compression. Typical application fields include earth moving equipment, drilling equipment, crusher jaws, excavator teeth, cones, hammermill hammers and cold cutting tools. |

| Metal-Cored MIG Hardfacing Wire | AI-17600 | DIN 8555: MSG 6-GF-60-GP EN 14700: T Fe 8 | AI-17600 is a premium seamless gas-shielded cored wire for the hardfacing of parts subject to the combination of extreme impact, pressure, and abrasive wear. Outstanding weldability with low spatter, especially for out-of-position hardfacing. |

| Solid MIG Hardfacing Wire | AI-1705Mn | AS/NZS 2576 ER1215-B6 | AI-1705Mn is a gas shielded surfacing and joining wire used extensively as a buffer layer or build-up on 14% manganese (Hadfield) steel, carbon and other steels prior to hardfacing. It is also extensively used for joining manganese steel to itself or to dissimilar steels. By way of its high chromium content, AI-1705Mn is suitable for one-wire hardfacing where work hardening can be expected. Applications include: Rebuilding of railway frogs and crossovers, railway lines, shovel track pads, and all types of crushers, hammers, manganese steel components, bucket repair and hardfacing, ball mill liners, many earthmoving, quarrying and mining areas. |

| Open-Arc Flux-Cored Wire | AI-1505 | AS/NZS 2576-1215-B7 AWS/ASME IIC SFA 5.21 : FeMn-Cr | AI-1505 is an open arc surfacing and joining wire used extensively as a buffer layer or build-up on 14% manganese (Hadfield) steel, carbon and other steels prior to hardfacing. It is also extensively used for joining manganese steel to itself or to dissimilar steels. By way of its high chromium content, AI-1505 is suitable for one-wire hardfacing where work hardening can be expected. Applications include: Rebuilding of railway frogs and crossovers, railway lines, shovel track pads, and all types of crushers, hammers, manganese steel components, bucket repair and hardfacing, ball mill liners, many earthmoving, quarrying and mining areas. |

| Open-Arc Flux-Cored Wire | AI-1543 | AS/NZS 2576-2460-B7 DIN 8555 MF 10-GF-65-G | A high quality complex carbide surfacing alloy giving exceptional resistance to all types of abrasion. Deposit achieves full hardness in first layer. Microstructure - primary carbides, M7C3 eutectic carbides and Nodular Niobium carbides (spherical) in a pearlitic matrix. Applications include: Groundnut oil expeller screws, brickwork extruder augers and mixers, wear plates, screens in the coal industry, bucket teeth on bucket-wheel excavators, shovel bucket teeth and lips. |

| Open-Arc Flux-Cored Wire | AI-1545 | DIN 8555 EN 14700 MF 10-70-GZ T Fe 16-70-GZ | AI-1545 is a complex chromium carbide open arc wire. It has an austenitic matrix with complex carbides of different types: chromium rich hexagonal primary carbides, complex eutectic and globular niobium rich carbides. Applications include: sinter plant parts, greenawalt crushers, smelter ladle overlays, exhaust fan blades in pellet plants and sugar cane industry, pearlite crushers, bucket teeth and lips on bucket wheel excavators in the phosphate mines, chutes in blast furnace bell, blast furnace bell burden area. |

| Open-Arc Flux-Cored Wire | UTP VANADIUM 500 | Open-Arc flux cored wire for manual or fully automatic on-site "arcing" of sugar mill rolls in view of enhancing the gripping surfaces excessive wear taking place on the rolls during crushing. Special Chromium/Vanadium alloy and homogeneous droplet transfer. | |

| Open-Arc Flux-Cored Wire | AI-1558 | DIN 8555 MF 6-GF-60-GP | A cladding or build-up alloy containing finely dispersed Titanium carbides in a hard, high chromium martensitic matrix. The deposit is heat treatable and forgeable. Applications include: Crusher cylinders, crusher hammers, agricultural tools, asphalt tools, car shredder, asphalt mixer blades, shovel bucket teeth and lips, bulldozer blades, cane knives and shredders, gyratory crusher mantles, bed knives and anvils in the wood pulp industry. |

| Open-Arc Flux-Cored Wire | AI-1558NbV | DIN 8555 EN 14700 T Fe 16-60-G | Highly abrasion and impact open arc hardfacing wire. For Applications requiring an extreme combination of wear resistant properties. |

| Open-Arc Flux-Cored Wire | AI-1568 | AS/NZS 2576 2360 B7 DIN 8555 : MF 10-GF-65-G | AI-1568 is a high quality-surfacing alloy designed for continuous, open arc cladding. The alloy will produce coatings, which have excellent resistance to abrasion, even when service conditions include some impact and corrosion.Alloy is particularly successful in applications involving gouging and high stress abrasion in heavy industry. It is suitable for application on to manganese steels. Applications include: Asphalt machinery, palm oil expeller screws, ground nut oil expeller screws, slurry pipes, bends and fittings, pug mill augers, catalytic converter pipes, screw conveyors, dredge pump impellers and casings, shovel bucket teeth and lips, dredge cutters etc. |

| Open-Arc Flux-Cored Wire | AI-1579 | DIN 8555 : MF G-GF-40-G | AI-1579 is an open arc, alloy cored wire developed primarily for the semi or fully automatic on-site surfacing of cast-iron or steel in applications where there is a combination of heavy impact and abrasion. The alloy consists of Cr7C3 carbides in an austenitic matrix, which results in a deposit, which provides an economical solution for general hardfacing over a wide variety of applications. AI-1579 has the characteristic of being able to be clad over contaminated surfaces and has an improved deposit efficiency when compared with other wires and electrodes. Applications include: An excellent alloy for use in other areas such as crushers (jaws, hammers, mantles etc), bucket repair, earthmoving equipment, mill liners, grizzly bars etc. |

| Open-Arc Flux-Cored Wire | AI-1579Nb | DIN 8555 : DIN EN 14700 MF 10-70-GZ T Fe 16-70-GZ | AI-1579Nb is a C-, Cr-, V-, Nb- B flux-cored wire designed for parts that are exposed to extreme mineral wear with light impact stress. The weld deposit has a very high scratch hardness. Typical applications are sinter plants, lignite mining bucket wheels, drag-line buckets and chains, gravel mining, sand dredging, and ground engaging tools in the agricultural sector. |

| Gas-shielded MIG Hardfacing Wire | AI-1732 | DIN 8555 | DIN EN 14700 MF 10-45-CGT | T Fe 14-45-CGT | AI-1732 is a tubular wire for hardfacing applications, resistant to wear and corrosion. The deposit is Cr- Ni- Mo alloyed and is used for corrosive as well as abrasive wear. AI-1732 can be used as a substitution for Stellite 6 where high temperature operation is not critical. The alloy can be additionally machined with carbide tools. Applications include: Press screws and kneader for meat processing and feeding stuff industry, chemical industry, palm oil screws, conveyer screws. |

| Gas-shielded MIG Hardfacing Wire | AI-1735 | DIN 8555 MF 6-GF-50-CT | Special Iron-Chromium-Cobalt-Molybdenum alloy designed to resist metal-to-metal wear, fatigue, oxidation, cavitation and corrosion at high temperature. The typical hardness can be achieved in the first layer. |

| Gas-shielded MIG Hardfacing Wire | AI-1779VC | DIN EN 14700: T Ni20 DIN 8555: MF21-55-CGZ | Tungsten carbide MIG wire, in a nickel matrix hardened with refractory carbides. |

| Gas-shielded MIG Hardfacing Wire | AI-1735 | ||

| SAW Submerged Arc Hardfacing Wire | AI-1642 | AI-1642 is an alloy specially produced for sub-arc applications where build up and hardfacing of carbon steels is required. This alloy offers resistance to the combined effects of abrasion and impact. AI-1642 has a microstructure of bainite + martensite. It has excellent machineability and can be oxy cut. Applications: AI-1642 is used as a build up and cladding alloy on crawler tractor rollers and idlers, shafts, cylinders, mine car wheels and crane wheels. |

|

| SAW Submerged Arc Hardfacing Wire | AI-1685 | DIN 8555: UP 6-GF-55-GT | AI-1685 is a martensitic alloy giving excellent resistance to metal-to-metal and low stress abrasive wear with impact and high compressive stresses. The deposit is heat treatable and forgeable. Applications: Suitable for steel mill rolls, blast furnace bells (seat area), dredger-buckets, cylinders etc. |

| SAW Submerged Arc Hardfacing Wire | AI-1685L | DIN 8555: UPI-GF-300-GP | AI-1685L is a martensitic alloy giving excellent resistance to metal-to-metal and low stress abrasive wear suitable for steel mill rolls, blast furnace bells (seat area), dredger-buckets, cylinders etc. |